Every business wants to grow, but with business growth and expansion comes a multitude of new challenges. While it may seem simpler to outsource many of these new challenges, there are some aspects that business owners are reluctant to contract out.

Read MoreAs a fundamental building block in all businesses, supply chains have been undergoing dramatic changes over the past few decades as a result of globalization and advances in technology. Effective supply chain management has increased in importance for this reason and is crucial to business success whatever the industry.

Read MoreIndustrial robots were first invented in the 1960s, and the company General Motors used the first one. According to Mike Wilson, author of Implementation of Robot Systems, there were over 2 million robots installed in different industrial sectors in 2015. This number has increased as more and more manufacturers introduce robotic systems integration into their production lines. It’s one of the latest technologies, dubbed the future of manufacturing.

Read MoreWithout question, a primary factor for any equipment manufacturer in today’s competitive market is its ability to create and maintain innovative products that align with what clients need while keeping an eye on the future of their industry.

Read MoreCountless industries are turning to contract manufacturing, including medical device companies. A medical device contract manufacturer can make the entire medical product or a component of the medical device through injection molding. This may include life sciences products, medical circuit board assembly, and items used in medical research.

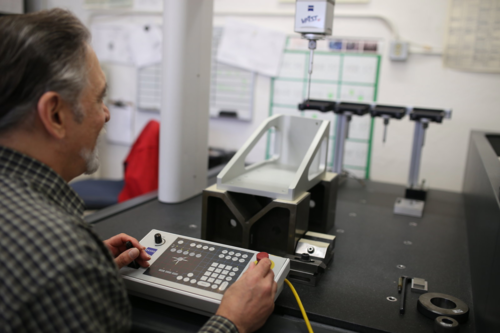

Read MoreJoin us on a tour of our 45,000 square foot facility located in San Jose, California. Applied Engineering is a Silicon Valley-based contract manufacturer, specializing in electro-mechanical builds.

Read MoreSpend a few minutes with our CEO Jack Yao and learn about how Applied Engineering can help meet your complex manufacturing needs.

Read MoreContract manufacturing, when you outsource manufacturing of your product line, enables you to have your products manufactured without the resources and capital needed to have your own factory. When looking for contract manufacturing services, your requirements will depend on your product manufacturing needs. For example, you may or may not require a company that offers CNC machining capabilities and complete assembly.

Read MoreMany companies, regardless of industry, operate under guidelines, standards, or regulations. A governing body or authority may establish these regulations, and the company may be legally required to follow them or voluntarily agree to meet these standards.

Read MoreDo you need intricate parts or products assembled in a controlled facility? Learn more about clean room assembly...

Read MoreWhen it comes to fabrication, you have options, and the option that will work for you depends on your current needs and long-term goals. Build to print and design and spec are two different types of contract manufacturing. To help you understand the differences, similarities, and benefits of these two processes, we have put together the following quick guide.

Read MoreLearn about the seven types of additive manufacturing, each with its own processes, methods of layering, and equipment.

Read MoreNo doubt that 2020 has been a challenging year for most of us. In addition to battling the global pandemic, we have encountered event cancellations, unemployment, business shutdowns, wildfires, stock market volatility or heaven forbid, the loss of a friend or family member.

Read MoreHaving an experienced Supply Chain Team that can make smart choices is even more important in ensuring you are partnering with the right CM. Ideally, you are looking for a partner, not just a vendor, for a long-term partnership.

Read MoreWhat is the real “value-add” of a contract manufacturer to its customers? It is their people. How best to cultivate a winning team year over year? It could be… by empowering them through ownership of their company!

Read MoreA famous sage once said; “it’s good to look at the forest before staring at the bark of a tree”. A company’s culture is often an overlooked, important, aspect of improving product quality. So, before you dive into a specific quality problem, look at the “forest” – the Company Culture.

Read MoreMany of these Contract Manufacturers advertise a list of certifications. We recommend that you peel back the “Certification Curtain” in your investigations. Here are some things to look for as you are weighing your CM options…

Read MoreYou just came up with your latest prototype design idea. To reduce your fixed cost your company has decided on an outsourcing model. How do you aim your efforts towards a successful path?

Read MoreLearn the Top 7 Criteria to consider when picking a Contract Manufacturer!

Read MorePlease be advised that due to Applied Engineering’s projects involving medical devices, homeland security, telecommunications and semiconductor equipment, our operations are considered a part of the “Essential Infrastructure” as addressed in the recent COVID-19 Shelter-in-Place” declaration.

Read More